A successful implementation of HACCP is essential to provide safe, nutritious, and wholesome food to consumers.

That is why Food and Beverage manufacturers incorporate a Food Safety Management system called HACCP (Hazard Analysis Critical Control Point), which is designed to improve food safety across all steps of food from farm to fork, which in turn provides the Food and Beverage Manufacturers the consumer’s trust on their brand.

This article provides a comprehensive guide for the successful Implementation of HACCP for Food and Beverage Manufacturers.

You Might Also Like: Free GMP checklist for food industry!

What is HACCP?

Hazard Analysis Critical Control Point (HACCP) came into existence in 1960 as the world’s pioneer approach for evaluating and controlling food safety but later, because of its characteristics, it became an integral part of the food processing operations. The FDA defines HACCP as:

‘’A food safety management system in which food safety is ensured by identification and control of hazards (physical, chemical and biological) from food production, processing, storage, transportation, distribution and consumption of the finished product.’’

HACCP systems are implemented worldwide by the food and Beverage industries. The main agenda behind implementing HACCP lies in identifying, evaluating, and controlling food safety hazards to produce safe, nutritious, and wholesome food for consumers.

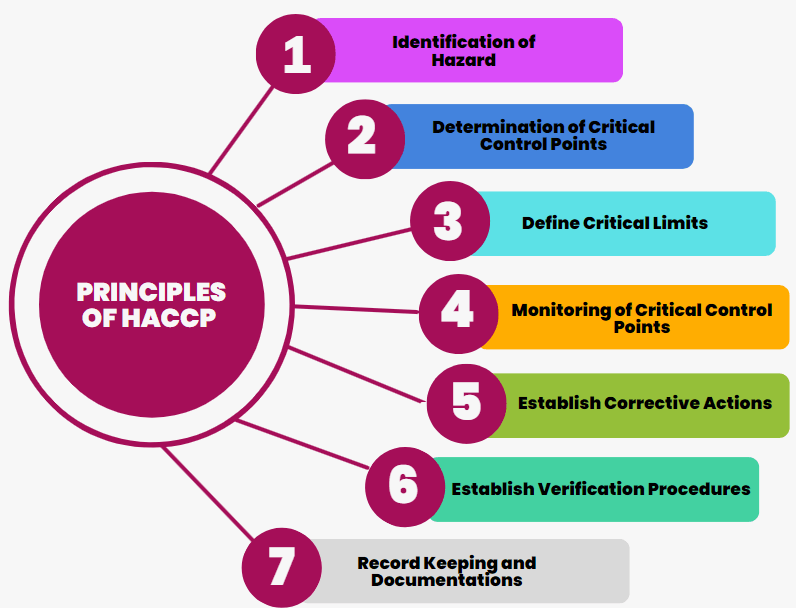

The leading 7 principles of HACCP can be followed to implement the HACCP system in any Food and Beverage industry.

Successful Implementation of HACCP Plan for F&B Manufacturers

Each process or product has its own HACCP plan, which identifies potential hazards and the controls in place to guarantee that they are removed or regulated to ensure appropriate levels in the food product.

Unfortunately, not every organization can benefit from the same HACCP template. Your HACCP plan should cover your company’s specific hazards and control points. Creating a HACCP Plan strategy from the start may appear to be a tough process. The answer, as always, is to surround oneself with the proper people.

The following are the steps for establishing a proper HACCP Plan for a food and beverage company.

Step 1. Build a HACCP Team

Bringing together a diverse team is the first stage in developing a HACCP strategy. Engineers, production managers, hygiene and safety specialists, microbiologists, and quality assurance specialists will be among those involved. On possible biological, chemical, and physical concerns, you may need to consult with other specialists.

Step 2. Describe the Product

Describe your product or service once you’ve assembled your team and chosen your contractors. What type of cuisine will you offer, what ingredients will you utilize, and how will it be prepared? Because the temperature of the food must be maintained, you must also determine how to distribute your product (frozen, refrigerated, or at room temperature).

Step 3. Specify the Intended Use of Product

When developing a HACCP strategy, you must consider both your product and your target audience. Children, the elderly, and persons with dietary allergies all require unique considerations, which should be addressed in the plan.

Step 4. Build the Flowchart

All of the processes in the HACCP process should be explained clearly and simply in the flowchart. Each recipe at a restaurant, for example, should have its flowchart. It should include not just internal process specifics but also supplier information and distribution best practices.

Step 5. Confirm the Flow Diagram on Site

The HACCP team should inspect the flow diagram on-site to ensure that it is accurate. When the HACCP plan is incomplete, it’s critical to prepare the necessary adjustments, as well as modify and enhance the strategy.

7 Principles of HACCP Chart

After the completion of the first 5 preliminary steps of the HACCP Plan, there are seven principles of HACCP that are considered to be the core steps for implementing HACCP in food firms.

Step 6. Identification of Hazard

The first principle of HACCP in implementing a HACCP in the Food and beverage industries is the “Identification of Hazards.” The term “Hazard” can be defined as “Anything which has the potential to cause danger.” Hazards are usually classified into three types:

- Physical Hazard:These include the presence of stones, nuts, bolts, dirt, foreign objects, etc. presence in the food.

- Chemical Hazard:These include the presence

0 of pesticide residues, additives, cleaning chemicals, or sanitizer presence in the food. - Biological Hazard:The presence of microbes, fungi, insects, and pests are included in the biological hazards.

The first principles of HACCP include listing all these hazards that could be the source of sickness for a consumer upon consumption of food or any other misfortune while working in the food vicinity.

Some of the main food processing steps where hazard analysis should be performed in any food and beverage industry include:

- Raw Material and Finished Product Storage

- Time and Temperature Specifications

- Worker’s Personal Hygiene

- Transportation of the Product.

These processing steps, as well as some food commodity-specific steps, should be considered for “Hazard Identification” to ensure a reliable and transparent HACCP system for any food industry.

Step 7. Determine Critical Control Points (CCP)

The next principle of HACCP is the determination of critical control points. A critical control point (TCP) is defined as “the points where control must be applied to ensure food safety at the further stages.” These critical control points are usually determined with the help of specific decision trees in food facilities.

Determination of all CCPs helps food manufacturers focus on these points and implement extra checks to ensure food safety at all further stages.

Some common critical control points in food industries include

- Cooking Time and Temperature

- Storage Time and Temperature

- Raw Material Composition

- Food Processing Steps

Step 8. Determine Critical Limits (CL)

For all determined critical control points, a critical limit is set for all of them. Critical Limit (CL) can be defined as “the limit that separates acceptance and rejection of the product.”

The main advantage of these limits is that a range is defined (maximum or minimum limit) for each CCP, and once the range exceeds the defined levels, the action plan can be implemented accordingly. In this way, the smooth functioning of all the food processing operations is carried out in the food and beverage industries.

A common example of a critical control point and critical limit is provided in the table:

| Critical Control Point | Critical Limit |

| Cooking Time | 5-10 min |

| Cooking Temperature | 165°F to 175°F |

| Food Ph | 6-6.5 |

| Cereal Grain Composition | 12-13% Moisture Content |

Step 9. Monitoring of Critical Control Point (CCP)

In this principle of HACCP, a critical control point is monitored by developing suitable inspection procedures to check whether the critical limit is under control or not.

Monitoring procedures of each critical control point include

- SOP for monitoring CCP

- Inspection frequency

- Inspection tool

- Inspection Responsibility

The effective monitoring procedures result in a robust HACCP management system for food and beverage manufacturers.

Step 10. Establish Corrective Actions

HACCP Plan for food manufacturers establishes documented corrective actions in case the results of critical control point monitoring indicate that the critical limit is breached.

The main advantage of this principle is that predefined corrective actions help control any possible hazards, which in turn fulfills food and beverage manufacturers’ ultimate goal of food safety.

| Critical Control Point (CCP) | Critical Limit (CL) | Monitoring of CCP | Corrective Actions |

| Cooking Temperature | 165°F to 175°F | 145°F | Continue heating until temperature attains the defined range |

| Cereal Grain Composition (Moisture content) | 12-13% Moisture Content | 20% | Lot discarded |

Step 11. Establish Verification Procedures

Documented Verification procedures are another essential principle of HACCP to ensure the smooth and continuous working of all the food processing steps.

Verification procedures usually include:

- Conducting regular audits

- Calibration of equipment

- Management Review Meetings

- Third-party inspections

Step 12. Record Keeping and Documentation

In HACCP, record-keeping and Documentation play a crucial role. Food manufacturers implementing HACCP must maintain records from food manufacturing to food retail.

Record keeping and documentation may vary from industry to industry, but it may include:

- Raw Material lists

- Risk Assessments

- Critical control points and required limits of the food items

- Employees hygiene records

- Traceability Records

In food processing facilities, all this information is recorded in a controlled format and a master list of documentation is maintained efficiently for the record-keeping system. Implementing all these steps in any Food and beverage industry ensures food safety and improves the overall efficiency of food processing operations.

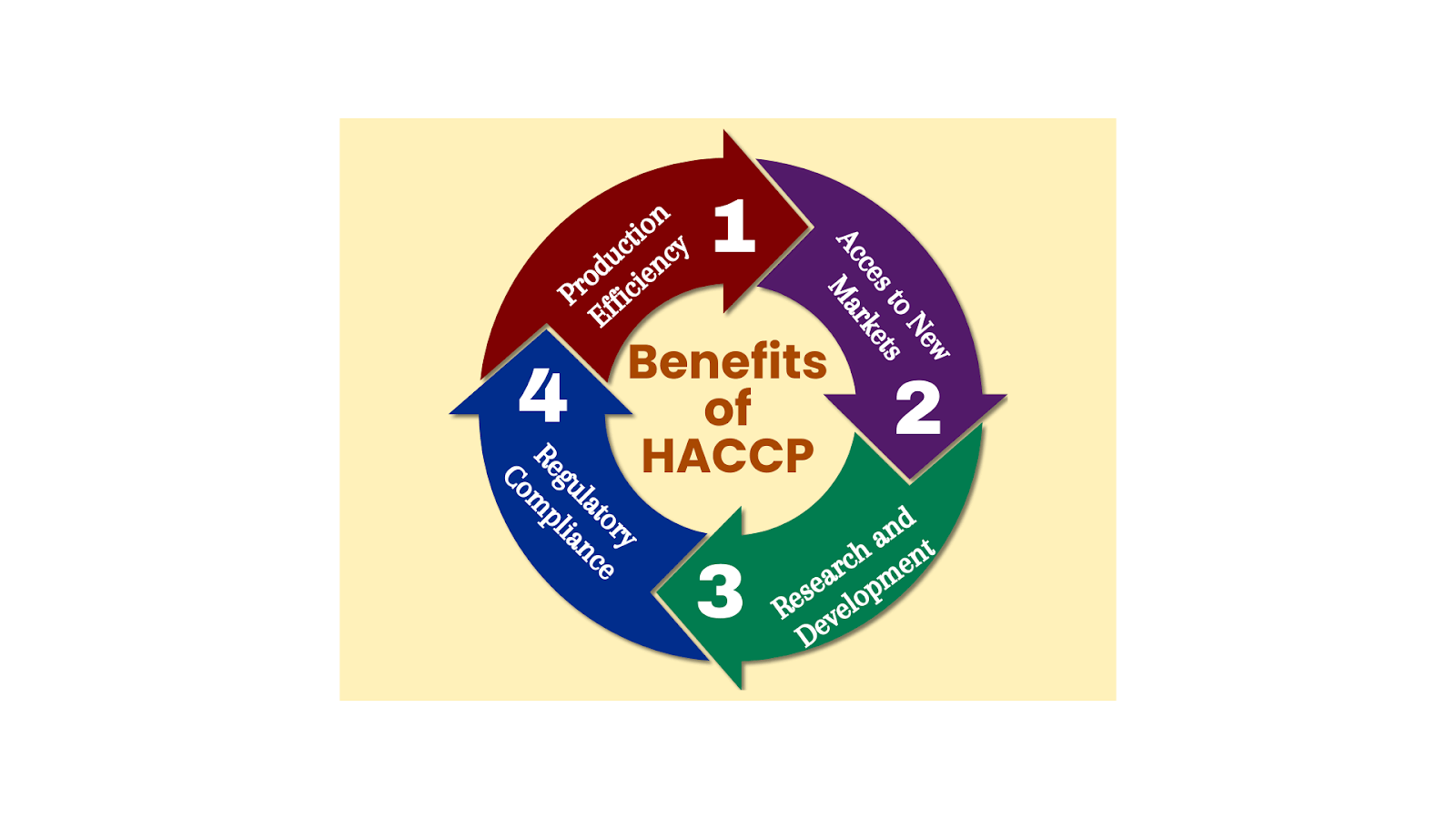

What are the Benefits of Implementing HACCP?

Implementing HACCP in your food and Beverage Industry provides numerous benefits in addition to food safety, which is ultimately linked with improved business growth of food and beverage manufacturers.

Following are four primary benefits of implementing HACCP for food and Beverage Manufacturers.

1. Improve Production Efficiency:

HACCP identifies the potential hazards associated with all processing steps in food industries. By controlling these hazards, food manufacturers can improve their production efficiency by reducing production delays and product recalls. These measures will save the extra cost for food manufacturers, which can surely boost the profit margin of food and beverage manufacturers.

2. Access to Domestic and International Markets:

Implementing HACCP in your food industry increases the food manufacturer’s product access to domestic and international markets because nowadays all developed countries demand HACCP certification for food products to import and export food items. Additionally, domestic sales of HACCP-certified food items increase because of consumer trust in HACCP-certified items.

3. Research and Development:

Implementing HACCP in food industries provides research and development benefits to the company because all processing steps are constantly evaluated at defined intervals, which can help companies improve their existing processes and develop new products.

4. Compliance with National and International Regulations:

The HACCP system is accepted worldwide. By implementing HACCP in any food industry, manufacturers can comply with all the national and international regulations, saving them from any extra fines and legal procedures. This compliance will also help them get approval from the respective regulatory agencies for new products

Learn More With AHF

Implementing a successful HACCP system is a fundamental to ultimately drive your business’s growth and reputation.

With the increasing global emphasis on food safety, aligning HACCP principles with other standards such as halal are the key to penetrating new markets.

Interested in learning more? Reach out to AHF through +1 (630) 759-4981 or info@halalfoundation.org for a free consultation!

Frequently Asked Questions (FAQs)

Q: What is the First Step in in Developing an HACCP Plan?

A: The first step in developing an HACCP plan is to build a HACCP team. This team should consist of individuals with diverse expertise, including engineers, production managers, safety specialists, microbiologists, and quality assurance experts.

Q2: How Do I Set Critical Limits in a HACCP Plan?

A: Critical Limits (CL) are specific thresholds at CCPs that separate acceptable from unacceptable conditions. These limits are set based on factors like temperature, time, pH, and moisture content to ensure that food remains safe for consumption.

Q3: What Should Be Included in the Monitoring Procedures for HACCP?

A: Monitoring procedures should include standardized operating procedures (SOPs) for each CCP, the frequency of inspections, the tools used for monitoring, and the personnel responsible for conducting these inspections. Consistent monitoring is key to ensuring compliance with HACCP standards.

Q4: What is the Purpose of Setting Critical Control Points (CCP) in a HACCP Plan?

A: Critical Control Points (CCPs) are stages in the food production process where control can be applied to prevent or eliminate food safety hazards. Identifying and monitoring these points is crucial for maintaining the safety of the food products.

Azmi is a dynamic content and client development professional at the American Halal Foundation, blending his passion for the halal lifestyle, history, and travel with sharp market insights. Known for his attention to detail and strategic approach, he crafts impactful content that drives engagement and strengthens AHF’s connection with global audiences.